What If You Could 3-D Print Dentures?

What If You Could 3-D Print Dentures?

3-D printing is taking the world by storm. What if you could 3-D print dentures? Well, you can, and clever people are already doing it.

In 2021, an article in a leading Perth newspaper featured a story on this very topic and claimed a local dentist as the sole innovator currently in this space. Perhaps, things have changed since then, as we know technology moves at a rapid pace. 3-D printing technology is potentially the most exciting thing to have happened to dentures since they stopped making them out of wood. Splinters aside folks, this technology may well revolutionise the way dentures are manufactured here in Australia and around the globe.

3-D Printed Dentures Are All About The Fit

Dentistry has been using digital computer technology for quite a few years in the design and fabrication of crowns, inlays, and implants protheses. CAD/CAM technology has drastically improved the process and the finished products in the denture and accessories segment of dentistry. 3-D printing is just the next step in the evolution of dentures taking them to a whole new level. Digital scans of the patient’s mouth delivers far greater accuracy for a much better fit. Customising dentures to exactly fit a client’s requirements ensures a more comfortable and secure fit. Doing away with mass produced dentures will put an end to bad fitting experiences and outcomes.

These 3-D Printed Dentures Can Speed Up The Process

Traditionally, handmade dentures take some time to be ready for a client, even after the laborious measuring and fitting process is completed. The 3-D printing advantage will offer better customisation and a potentially faster turnaround for those patients seeking dentures. When you need dentures you don’t want to be waiting around for an age until they are ready. Imagine perfectly tailored dentures that fit like they were made by nature for your specific oral cavity requirements. Fitting the exact shape and size of every patient’s mouth will substantially improve dentistry outcomes in the 21C.

What if you could 3-D print dentures? Well, another advantage of this technology would see these opportunities. The digital file for your 3-D printed dentures will, also, enable any changes and alterations to be made quickly without having to reinvent the wheel. Meeting the needs of a client with a strong bite or who may be missing multiple teeth will be much easier for dentists. This technology offers considerable scope for improvement to a sector, which has long been somewhat run of the mill in terms of ultimate patient satisfaction. Dentures have not always fulfilled the hopes and expectations of clients in the past.

Another positive, potentially, will be the cost effectiveness of this technology. A more streamlined fitting process will reduce the number of sessions a client will be required to have. 3-D printing dentures should result in lower costs for dental clients going forward. However, it is very early days in the introduction of such a ground-breaking technological innovation. It may be some time before we see prices tumbling down and patients making real savings on getting their dentures.

How Much Do Dentures Cost?

In Australia in 2022/23 a full set of traditionally made dentures costs around $4,000 and upwards. In the USA, where 3-D printed dentures are more commonly available, dental labs are quoting dentists around US$500 for a full set of 3-D printed dentures, which would be around A$720. The dentist would add on around another A$1,000 I would speculate. Ultimately, and in time, the savings could be substantial, if economies of scale for the materials used in the printing process can be achieved in Australia’s much smaller market. Dentistry has never been cheap and I cannot see that happening any time soon.

What if you could 3-D print dentures? The positives for 3-D printing as the future for dentistry and denture manufacturing are mounting up. It is an exciting time to be a dentist, with technology driving the field into ever more interesting directions. This highly innovative technology offers a cornucopia of promising benefits, including sharper accuracy, better customisation, and potentially greater cost-effectiveness.

Over time and their history, dentures have been made out of wood, bone, animal teeth, wire, and even other people’s teeth. Ivory was popular for quite a while, porcelain, vulcanite, acrylic resins and plastics which are in use now. 3-D printing acrylic resins.

“Three-dimensional (3D) printing is increasingly being utilised in the dental field because of its time-saving potential and cost effectiveness. It enables dental practitioners to eliminate several fabrication steps, achieve higher precision, and attain consistency in complex prosthetic models. The properties of 3D-printed resin materials can be affected by many factors, including the printing orientation (PO) and insufficient post-curing time (CT).”

– Science Direct

Cutting Edge Applications in Dentistry for 3-D Printing

Another cutting edge application for 3-D printing in the dental and orthodontic field is bioprinting. This Star Trek like technology aims to create replacement human tissues using the patient’s own cells. Yes, you read that right. Printing is going to a whole other level folks. The days of , mere, paper jams are well and truly over.

“In this research, bioprinting technology was applied to produce a three-dimensional dentin–pulp complex with patient-specific shapes by inducing localized differentiation of human dental pulp stem cells within a single structure. A fibrin-based bio-ink was designed for bioprinting with the human dental pulp stem cells. The effects of fibrinogen concentration within the bio-ink were investigated in terms of printability, human dental pulp stem cell compatibility, and differentiation. The results show that micro-patterns with human dental pulp stem cells could be achieved with more than 88% viability.”

– Sage Journal

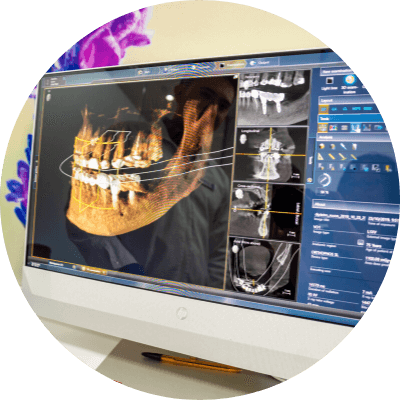

Yet another example of innovative 3-D printing uses in dentistry involves digital tools like cone-beam computed tomography scans (CBCT). Combining this with 3-D printing facilitates dentists being able to create amazingly accurate digital models of a patient’s teeth and jaw. The better the data the better the fit for implants and dentures. Surgical guides can be established via this precision planning, which means greater rates of success in surgery with far fewer complications.

Orthodontics is benefitting from 3-D printing as well, with customised aligners, braces, and retainers. Better fittings mean more comfort and much better results for clients. Patients with bruxism and TMI disorders can have their night guards and splints customised via 3-D printing too.

What if you could 3-D print dentures? In Australia, the application of this exciting new technological innovation has only just begun. However, the future looks bright for patients and dentists. These things are happening in America now and we are not too far behind.

Note: All content and media on the Sunbury Dental House website and social media channels are created and published online for informational purposes only. It is not intended to be a substitute for professional medical advice and should not be relied on as health or personal advice.

Services Mentioned

Related Articles

Dentistry Has Its Dinosaurs, Its Old Fossils & Its Neanderthals

We human beings, we Homo sapiens have trouble coming to terms with deep time. What is deep time? Anything much more than last week (LOL). No, stuff that happened eons ago is outside of our ken. We are so very much caught up with our own concerns and future. Thinking...

What’s New In Tooth Decay? Another Bacteria, That’s What

Four is quite a significant number to us humans. We like it. We live by it. The Chaldeans of Babylon loved it for their system of terrestrial and meteorological phenomena that told an astrological future encompassing earth, water, air and fire. Aristotle ascribed...

What’s With Teeth Terms? Mulberry Molars? Flux? Butterfly? Cauliflower? Tombstone?

It’s often supposed that the roots of English are predominantly Greek and Latin. Understandably so. Words are assimilated into the language from other dialects as well, like French and Arabic. From the approximately 170,000 English words currently in use,...

Toothless: What’s Life Like Without Any Teeth?

It was Elon Musk who, in 2017 said, “If anyone thinks they’d rather be in a different part of history, they’re probably not a very good student of history. Life sucked in the old days. People knew very little, and you were likely to die at a young age of some horrible...